New Innovations From Erdie

Automated shipping and new challenges

As the trend of e-commerce shows no signs of slowing down, improving efficiency in shipping houses is more important now than ever. According to Forbes, e-commerce sales increased 50% during the pandemic alone.

As more products are being shipped daily, shipping hubs have moved to fully automated scanning systems to account for the higher traffic flowing through their facilities. Automation speeds up the workflow and reduces shipping costs in most applications. Modern automated shipping plants utilize conveyor systems and robotic arms to pass the packages and envelopes through the facility, which reduces the need for a large human workforce. While, in most cases, this has provided cost savings for many styles of packages, mailing tubes have remained costly by comparison.

Mailing tubes are known for their unmatched durability when shipping fragile items and products. Strength is shared across all tubular designs; a tube is harder to crush, whether steel or paper. However, it is the tubular design that prevents mailing tubes from benefiting from the cost savings of automation.

What is the main disadvantage of shipping tubes?

What is the main disadvantage of shipping tubes?

Tubes roll, especially on conveyor belts, which makes it very difficult to scan mechanically. This means that mailing tubes must be scanned by hand to avoid packages disappearing if they are not properly checked in. Naturally, this raises costs due to the increased workforce but is also a hindrance to shipping hubs attempting to go fully automated.

Getting around the system with different methods

Some businesses have begun placing mailing tubes inside standard boxes before shipping them to avoid higher shipping costs. It's a practical solution, but it doesn't decrease the price dramatically as the business will have to pay for additional shipping materials.

However, there are new innovations on the horizon that can provide better results.

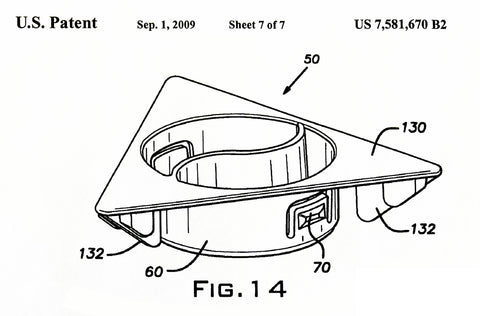

Erdie Industries is currently developing a new style of endcap that will prevent rolling on conveyor systems, allowing for mailing tubes to be shipped just like a regular cardboard box. Erdie Industries created the locking end cap, known as the Twist-N-Pull®. By altering the design of this endcap, mailing tubes can again be both superior in shipping cost and strength.

Solving multiple issue with one design

Based on the patent drawing to the right, one can see that fins have been added

(see 132). Not only does this design attempt to resolve the conveyor belt issue, but it also prevents snagging on roller systems.

There is no official release date set for this product, but if you would like to hear more from Erdie about new inventions and green solutions, please sign up for our newsletter below.